SPARE PARTS FOR AUTOMATIC CAPSULE FILLING MACHINE

SPARE PARTS AND CHANGE PARTS FOR AUTOMATIC CAPSULE FILLING MACHINE

Description: Spare parts and change parts for automatic capsule filling machines are essential components that contribute to the efficiency, adaptability, and longevity of the machine. These parts encompass a range of interchangeable elements that can be replaced, adjusted, or maintained to ensure the continuous and reliable operation of the automatic capsule filling equipment in pharmaceutical and nutraceutical manufacturing.

Specifications:

- Changeable Dosage Discs: Interchangeable dosage discs for precise control over the amount of powder or granules dispensed into each capsule, accommodating different formulations.

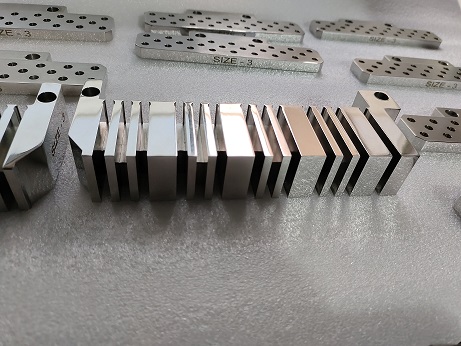

- Capsule Holders: Adjustable capsule holders that can be changed to fit various capsule sizes (00, 0, 1, 2, 3, 4) for flexibility in production.

- Tamping Pins: Interchangeable tamping pins designed for different capsule sizes, ensuring accurate and consistent tampering during the filling process.

- Sealing Bells: Replaceable sealing bells for efficient and reliable capsule sealing, preventing leaks and maintaining product integrity.

- Auger Components: Changeable auger components for machines that use auger-based filling mechanisms, allowing adaptation to different powder types.

- Brushes and Wipers: Interchangeable brushes and wipers for the cleaning and maintenance of the dosing and filling mechanisms.

- Vacuum Parts: Replaceable vacuum parts for machines that utilize vacuum-assisted capsule handling, ensuring proper suction and release of capsules.

- Material Compatibility: All components are constructed from materials compliant with pharmaceutical industry standards, ensuring cleanliness and preventing contamination.

- Quick-Change Design: Engineered with a quick-change design to facilitate efficient and rapid replacement or adjustment of parts, reducing downtime during production.

- Tool-Free Assembly: Where applicable, parts are designed for tool-free assembly and disassembly, simplifying the process of changing components.

- Precision Engineering: Each spare and change part is manufactured with precision to maintain the accuracy and reliability of the automatic capsule filling machine.

- Ease of Cleaning: Components are designed for easy cleaning, supporting adherence to hygiene standards in pharmaceutical manufacturing.

Benefits:

- Flexibility: Enables the automatic capsule filling machine to adapt to different capsule sizes, formulations, and production requirements, enhancing versatility.

- Minimized Downtime: Quick-change design reduces the time required for changeovers, minimizing downtime and maximizing production efficiency.

- Cost-Effective Maintenance: Allows for cost-effective maintenance by replacing specific components rather than entire assemblies or machines.

- Adaptability: Ensures the adaptability of the capsule filling machine to evolving production requirements and changes in the pharmaceutical product lineup.

- Consistency: Precision engineering of spare and change parts maintains the accuracy and consistency of the capsule filling process, contributing to product quality.

- Compliance: Parts are designed to meet regulatory standards for pharmaceutical manufacturing, ensuring compliance with industry requirements.

- Extended Equipment Lifespan: Regular replacement of wear-and-tear components can extend the overall lifespan of the automatic capsule filling machine.

- User-Friendly Operation: Designed to be user-friendly, with clear instructions for operators to facilitate the smooth replacement or adjustment of spare and change parts.

In summary, spare parts and change parts for automatic capsule filling machines are crucial for maintaining efficiency, adaptability, and reliability in pharmaceutical manufacturing, allowing for seamless adaptation to different production needs and formulations